From Friction Welding Machines to Parts, We Make It Happen

- Friction Welding Machines

- Global Service & Parts

World Leader in Friction

Welding Technology

World Leader in Friction

Welding Technology

Who Are We?

We are excited to announce our formal partnership with Machine Tools India, building on a strong working relationship developed over several years. This collaboration strengthens our presence in the region and enhances our ability to provide localized expertise and dedicated support to customers across India. Together, we look forward to advancing innovation and delivering value to manufacturers throughout the Indian market.

Rotary Friction Welding

We specialize in Rotary Friction welding in all forms – Direct Drive, Inertia, and Hybrid. Rotary Friction welding can accommodate various part geometries, being well-suited for applications across industries including automotive, construction, agriculture, and oil & gas. We manufacture a full line of machines including automated cells and specialty applications.

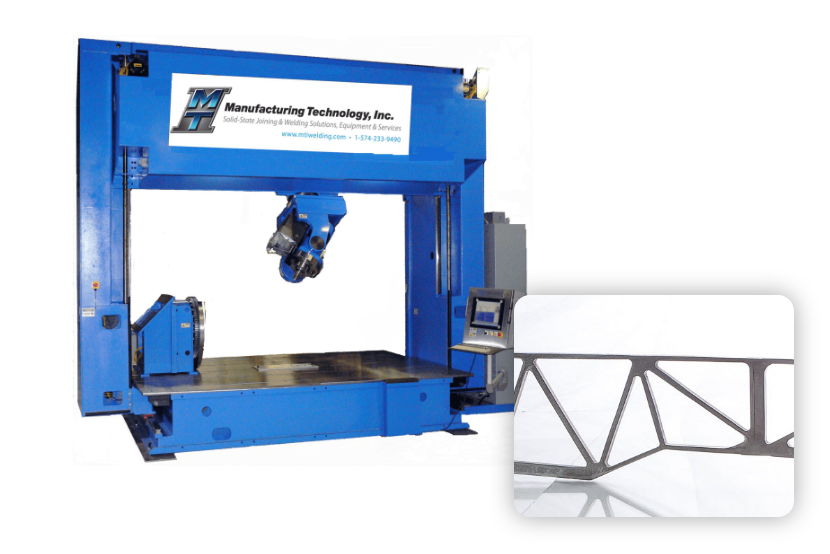

Friction Stir Welding

From electric vehicles on the ground to ships at sea and rockets in space, FSW delivers high-strength, low-distortion joints that transform assemblies across industries.

Building on this transformative technology, we have formed a partnership with STIRTEC, combining our global manufacturing footprint and expertise with STIRTEC’s advanced Friction Stir Welding (FSW) technology to deliver high-performance FSW machines to customers in India.

Low Force Friction Welding

Using decades of friction welding and solid-state joining knowledge, MTI has developed, designed, and manufactured Low Force friction welding machines that are operating in industry today. But what makes Low Force different from traditional friction welding?

Low Force Friction Welding is a technology in which an external energy source raises the interface temperature of the two joined parts. Unlike traditional methods, Low-Force friction welding significantly reduces the forces needed for a solid-state weld. This approach applies to the rotary process, offering substantial benefits.

Check Your Material Combination & Geometry

Can Your Application Be Friction Welded?

Compatible Welds

|

Not Seeing Your Combination Of Materials?

That doesn’t mean it can’t be done. Many of our material combinations are also proprietary. That’s why several of our customers use MTI’s in-house metallurgy lab, which will test your materials for strength and durability to see if friction welding is the right process for you.

Please note Weld strength is dependent on materials & geometry.

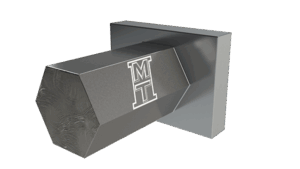

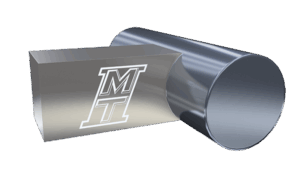

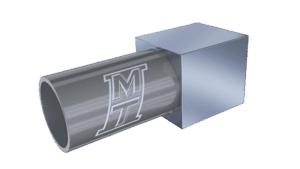

Joint Geometries

Friction Welding can join a wide range of part geometries

Let’s talk about the specifics of your project:

Friction Welding, Made Simple

Our simple, modern development process sets us apart from traditional, overwhelming processes. We help you find and navigate the best path to successfully implement friction welding into your part design and production. We stand ready to support you on your timeframe and wherever you may be in your journey to friction welding. We’ll build a machine for you that makes the part, we’ll make the part for you, or we’ll help you make a part better.

Friction Welding Machines

MANUFACTURERS UTILIZE & TRUST OUR FRICTION WELDERS FOR THEIR CRITICAL COMPONENTS

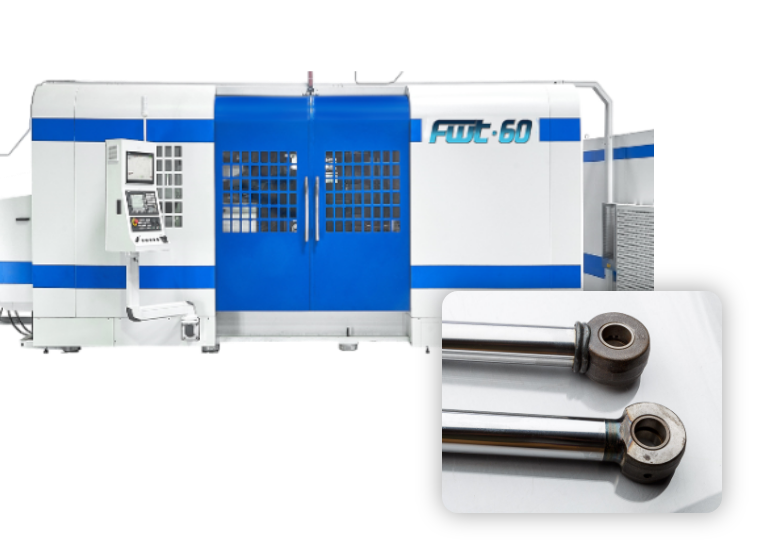

60T Rotary Friction Welder

One of our most popular models, the 60 ton can weld both solid and tubular components including piston rods and propeller shafts.

150B/BX/T Rotary Friction Welder

This model is a popular turbocharger machine but can also weld propeller shafts.

Rotary Induction

Found in MTI’s Low Force Innovation Center, the Low Force Rotary Lab Machine has an extensive history of R&D work and identifying possible applications for Low Force Friction Welding. With R&D quality process measurements, advanced process control and flexible tooling options, this machine is suited for a number of applications.

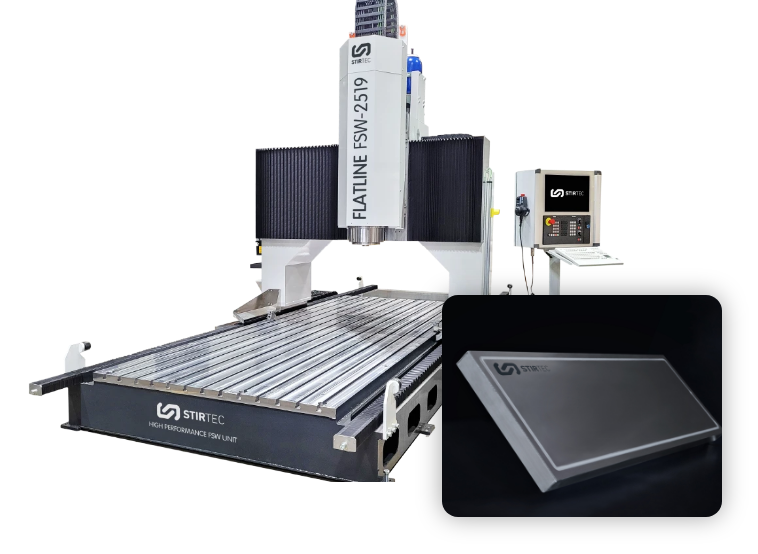

Flatline FSWC-2519

This machine model is highly efficient for the production of large full-EV battery trays and midsize battery systems. The open gantry design enables part handling simultaneously to the welding cycle without disruption to the production process.

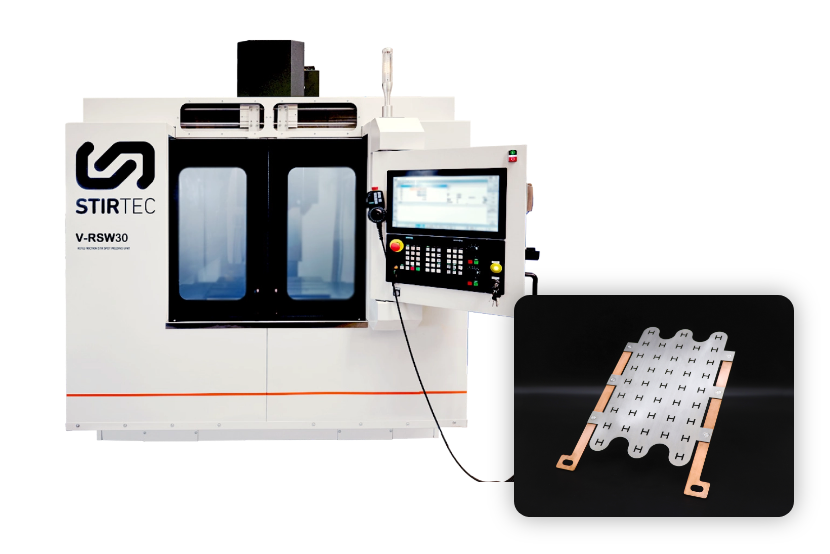

V-RSW30 | Refill Friction Stir Spot Welder

Stirtec presents the machine type V-RSW30 for industrial use of the innovative welding technique Refill Friction Stir Spot Welding (RFSSW).

GG Series Friction Stir Welder

The GG Series machines are the most versatile heavy section Friction Stir Welders on the market. Capable of welding complex contours with agility, the GG Series is the ultimate solution to welding complex train bodies on a massive scale.

WE SERVE THE INDUSTRIES THAT SHAPE THE WORLD

Underground, on the surface, and in the skies.

Friction Welding, in all of its forms, is used in a wide range of industries. At the forefront of innovation, we offer end-to-end Friction Welding solutions for virtually any industry.

- Astrospace

- Aerospace

- Automotive

- Defense

- Oil & Gas

-

Cutting

Tools

-

Electric

Vehicles

-

Construction

& Agriculture

- Astrospace

- Aerospace

- Automotive

- Defense

- Oil & Gas

-

Cutting

Tools

-

Electric

Vehicles

-

Construction

& Agriculture

Frequently Asked Questions

The Friction Stir Welding process uses a non-consumable pin tool to create frictional heat between two materials. As the pin tool spins, it “stirs” the two materials together, creating plastic deformation between 70-90 percent of the solidus temperature. Solidus is the highest temperature at which an alloy is completely solid. Plastic deformation changes the shape of the solid body without weakening the material.

Because Friction Stir Welding is a solid-state joining process, the two materials being friction welded never melt, and joining occurs below the solidus of the equilibrium phase for the materials. As a result, the metals better retain their original mechanical properties.

Because Friction Stir Welding creates extremely high-quality, high-strength joints with low distortion, the solid-state joining process is the preferred technology for welding aluminum sheets, extrusions, panels, and other products.

Friction Stir Welding is also commonly used to join dissimilar lightweight metals and hybrid electric vehicle applications.

There are several advantages to using friction stir welding, especially over fusion welding processes. Here’s just a few:

- Virtually Defect-Free Bonding: As a solid-state process, FSW avoids common fusion welding issues like shrinkage, cracking, and porosity.

- Superior Mechanical Characteristics: FSW creates strong, fatigue-resistant welds with minimal distortion.

- Machine-Controlled Process: FSW is highly repeatable and operator-independent, with real-time monitoring and control for consistent weld quality.

- Environmentally Friendly Process: FSW is clean and energy-efficient, requiring no consumables, gases, or heavy protective gear.

- Join Dissimilar Alloys: FSW can weld dissimilar metals without melting, preserving material properties and eliminating the need for fillers.

Rotary Friction Welding is a solid-state process in which one part is rotated at a high speed and is pressed against another part that is held stationary. The resulting friction heats the parts, causing them to forge together. MTI is the only company that offers all three types of RFW technologies - Direct Drive, Inertia, and Hybrid.

There are dozens of applications suitable for Rotary Friction Welding, but here is a list some of the most common examples by industry:

- Aerospace components such as engine rotor components, rotor assemblies, jet engine fan shafts, landing gear

- Automotive applications including drive shafts, bi-metallic valves, turbocharger shafts, pistons

- Construction and Agriculture parts such as hydraulic cylinder rods, piston rods, water pumps, track rollers

- Oil & Gas components including rock drill pipe, drill pipe and directional drill pipe

Rotary Friction Welding is a quicker, stronger and more environmentally friendly alternative to fusion welding processes such as electric arc or gas welding or high-energy processes like electron beam or laser welding. Other key benefits of Rotary Friction Welding include the ability to join bi-metallics or dissimilar metals, faster weld cycles, and minimal joint preparation.

The Low Force process uses an external energy source to raise the interface temperature of the two parts being joined, thereby reducing the process forces required to make a solid-state weld compared to traditional friction welding. The process applies to Rotary Friction Welding.

Machine Tools India Limited

284, Sultan Sadan II, West End

Marg Lane No 3, Saidulajab

Mehrauli, New Delhi – 110030, India

Let’s talk about your project

"*" indicates required fields

Friction Welding Technologies Pvt. Ltd. (FWT) is a privately-held, family-founded company headquartered in Pune, India, and is part of the MTI Group of companies. FWT specializes in transformational, standard friction welding solutions for manufacturing processes. Our leading-edge expertise is available worldwide on-site for industry applications such as aerospace, oil and gas, automotive, agriculture, construction, cutting tools, and defense.

© 2025 Manufacturing Technology, Inc.

Friction Welding Technologies Pvt. Ltd. (FWT) is a privately-held, family-founded company headquartered in Pune, India, and is part of the MTI Group of companies. FWT specializes in transformational, standard friction welding solutions for manufacturing processes. Our leading-edge expertise is available worldwide on-site for industry applications such as aerospace, oil and gas, automotive, agriculture, construction, cutting tools, and defense.

© 2025 Manufacturing Technology, Inc.